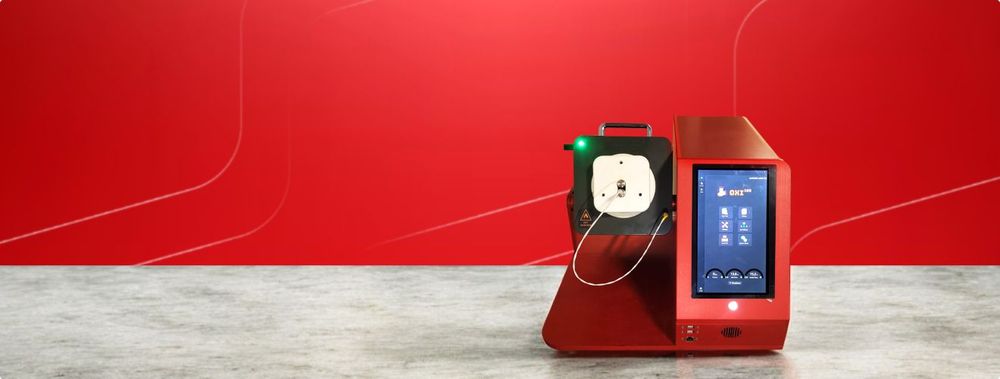

Designed to eliminate manual testing complexities and provide accurate, repeatable results, the VeroVis is the go-to instrument for labs, refineries, and industries that require stringent quality control over fluid viscosity.

Kinematic viscosity is a critical parameter that determines the flow characteristics of oils and fuels under various conditions. Ensuring that these fluids meet industry standards is crucial for optimizing performance, reducing wear, and preventing costly machinery breakdowns. The VeroVis is built with state-of-the-art automation, reliability, and advanced features to help companies maintain and enhance the quality of their operations.

Understanding Kinematic Viscosity

Kinematic viscosity is a measure of a fluid's resistance to flow under gravity. It is a key property that impacts the performance of lubricating oils, fuels, and other fluid products. Understanding viscosity is essential for ensuring that oils are capable of reducing friction, providing cooling, and maintaining the reliability of equipment in various environments. High or low viscosity can lead to operational problems, ranging from increased energy consumption to severe equipment damage due to inadequate lubrication.

The VeroVis helps industries assess viscosity with unparalleled accuracy. By providing consistent and reliable results, the VeroVis ensures that lubricants and fuels meet the desired specifications, ultimately enhancing equipment longevity and operational efficiency.

Key Features of the VeroVis

The VeroVis viscometer is designed with advanced features that allow users to perform viscosity analysis efficiently and effectively:

Wide Temperature Range

The device operates across a temperature range of 5°C to 150°C, providing great versatility in testing various types of oils and fuels. The VeroVis also supports chiller options for lower temperature requirements, ensuring that samples are tested under optimal conditions.

Atlantic Tube Design

Featuring a 350-fold viscosity range from 1 mm²/s (cSt) to 10,000 mm²/s (cSt), the VeroVis covers a wide range of viscosity measurements without requiring frequent tube replacements, saving both time and improving operational efficiency.

Preheating and Rapid Cooling

The VeroVis includes a sample heating function integrated with the sample holder, which ensures the sample reaches the required temperature for testing. The bath cooling system provides coolant inlets and outlets for rapid cooling of bath oil, helping to minimize the time between tests.

Automated Sample and Wash Handling

The VeroVis offers automated sample capacity for up to two samples, allowing multiple tests to be conducted with minimal intervention. The device also includes an automated washing and drying system with two solvent inputs, ensuring that each tube is cleaned thoroughly after testing to prevent contamination.

Accurate Temperature and Timing Control

The VeroVis features precise temperature control with a resolution of 0.01°C, allowing for highly accurate viscosity testing. Additionally, the device offers timing resolution down to 0.001 seconds, ensuring every measurement is highly precise.

User-Friendly Interface

The VeroVis comes with a 10.1-inch capacitive touch screen running on a Windows 10 operating system. This interface allows users to easily navigate through test options, monitor the status of ongoing tests, and manage data. The system also supports USB and Ethernet connectivity for data export, making it suitable for both research and industrial applications.

Benefits of Using the VeroVis

The VeroVis Fully Automatic Kinematic Viscometer provides a wide range of benefits that make it indispensable for companies seeking to optimize the quality of their fluid products:

High Accuracy and Precision

The VeroVis is designed to deliver highly accurate and repeatable viscosity measurements, reducing the variability that comes with manual testing. This accuracy ensures that lubricants and fuels are produced to the highest quality standards.

Time and Cost Savings

Automation significantly reduces the time required for each viscosity test and minimizes labor costs. The rapid preheating and cooling functions further contribute to operational efficiency by reducing downtime.

Versatile Testing Applications

The VeroVis's wide temperature range and viscosity measurement capabilities make it suitable for a wide array of applications, including oil analysis, marine fuel testing, hydraulic fluid testing, and base stock analysis.

Reduced Operator Intervention

The fully automated system means that the VeroVis requires minimal operator intervention, reducing the risk of human error and ensuring consistent results. The integrated washing and drying system also minimizes the need for manual cleaning, reducing labor efforts and increasing productivity.

Enhanced Data Management

The large storage capacity of the VeroVis allows users to store up to 10,000 test results, ensuring that data is available for analysis, traceability, and quality assurance. Results can be exported in PDF format, making it easier to share data across teams and departments.

Applications of the VeroVis

The VeroVis Fully Automatic Kinematic Viscometer is a versatile instrument that can be used in a variety of applications, including:

- Oil Refineries and Fuel Manufacturers

To ensure that lubricating oils and fuels meet industry standards and specifications.

- Automotive and Aerospace Industries

To evaluate the viscosity of lubricants and ensure that they maintain their properties in different operational environments.

- Power Generation Plants

To monitor the viscosity of lubricants used in turbines and other critical equipment, ensuring reliable performance.

- Industrial Manufacturing Facilities

To optimize machinery performance by ensuring that hydraulic fluids and lubricants meet the required viscosity specifications.

VeroVis: A Reliable Partner for Quality Control

The VeroVis Fully Automatic Kinematic Viscometer is an investment in quality and efficiency. By providing highly accurate, repeatable, and reliable results, the VeroVis helps organizations ensure that their products meet the highest standards of performance and reliability. This level of control helps prevent costly equipment failures, minimizes operational risks, and enhances the overall productivity of the facility.

In today's competitive market, where quality and efficiency are paramount, the VeroVis stands as an essential tool for laboratories, refineries, and industries that demand the best from their equipment and fluids. Vero Scientific is proud to offer the VeroVis as part of our commitment to providing advanced measurement technologies that help industries thrive.

For more information about the VeroVis and how it can benefit your business, reach out to Vero Scientific today. Discover how our state-of-the-art measurement solutions can enhance the quality and reliability of your products, ensuring long-term success.