The VeroXi Oxidation Stability Analyzer is designed to meet internationally recognized standards including ASTM D2274, ISO 7536, EN 16091, and IP 40. These standards ensure accurate, reliable, and reproducible results for oxidation stability testing. Compliance with these standards guarantees consistent quality control, minimizes testing errors, and ensures that the VeroXi is compatible with trusted industry protocols. This alignment is crucial for industries where precision and reliability are essential, such as automotive, oil, and gas.

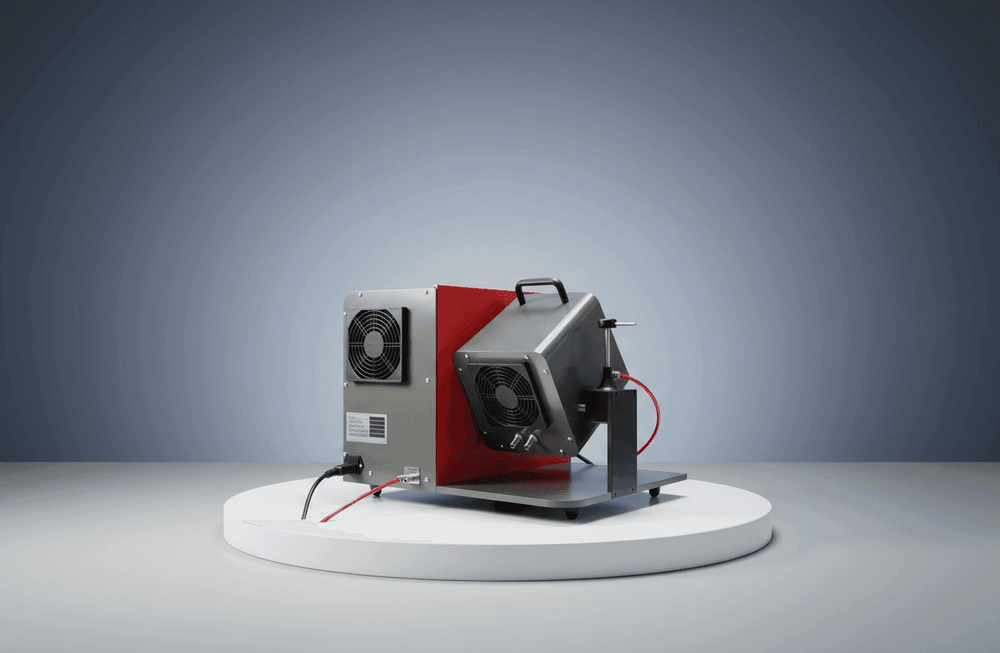

OXIDATION STABILITY ANALYZER

Detailed instructions for the setup, operation, and maintenance of the VeroXi Oxidation Stability Analyzer. Designed to ensure precise and consistent results, this guide covers all essential information for maximizing device performance and reliability.

Standarts

Correlations

Highlights

The VeroXi Oxidation Stability Analyzer provides accurate, reliable results for testing the oxidation stability of oils and other fluid samples, making it an essential tool for quality control and research applications.

The VeroXi offers a user-friendly interface and a straightforward process for preparing and testing samples. With features like customizable test methods, precise temperature and pressure calibration, and an efficient gas release function, it ensures high-quality results for every test. The device is capable of storing up to 10,000 test results, making it easy to track historical data and compare results over time. Its unique design includes a copper coil for efficient mixing, a stable oxygen supply system, and an intuitive test procedure that guides users through every step, from sample preparation to result storage. The VeroXi is a versatile and reliable solution for industries where oxidation stability is critical, ensuring the accuracy and consistency required for high-performance fluids.

Videos

Efficient Operation and Setup of the VeroXi - Step-by-Step Guide

- Detailed Sample Preparation: This feature demonstrates the precise sample preparation process, including the step-by-step addition of oil and distilled water, weighing the sample accurately, and ensuring proper placement of the copper coil. These steps are critical for ensuring the reliability and accuracy of the oxidation stability test results.

- Oxygen Supply and Pressure Settings: Learn how to connect the oxygen hose to the device and adjust the gas inlet pressure to 7 bar. This ensures that the device operates within the optimal conditions for accurate testing, maintaining a consistent and controlled environment for every test.

- Efficient Device Bath Setup: The video covers the process of adding distilled water to the device bath to ensure proper thermal contact and securely closing the bath cover. This step is crucial for maintaining stable test conditions throughout the process.

- Test Start Procedure: Walk through the steps for starting a new test, including entering operator details, selecting the appropriate ASTM method, and initiating the test. This ensures that the testing process is simple and efficient, with standardized procedures for consistent results every time.

Calibration, Maintenance, and Gas Control on the VeroXi

- Calibration of Temperature and Pressure: This feature explains how to perform precise calibration of the temperature and pressure settings on the VeroXi. By inputting values from certified sensors, users can ensure that the device provides highly accurate measurements, making the results more reliable for long-term testing.

- Leak Test Procedure: Learn how to perform a leak test, which is essential for checking the integrity of the device and ensuring there are no gas leaks during testing. This step helps maintain the safety and performance of the VeroXi.

- System Check for Device Maintenance: Discover how to use the system check feature to perform routine maintenance, including checking the functionality of the mixer, heater, and oxygen flow. This ensures that all components are working properly and ready for the next test.

- Gas Release Function for Post-Test Safety: The video also covers how to use the gas release function after completing a test. This step ensures that any remaining gas is safely removed, which is critical for maintaining the safety of both the operator and the device.

- History and Test Results Management: Explore the VeroXi's capability to store up to 10,000 test results. Learn how to access past results and use the history function to review, analyze, and compare test data, making it easier to track trends and maintain consistency in testing.

Technical Specifications

| Model | VeroXi - Oxidation Stability Analyzer |

| Standards Compliance | ASTM D2272, ISO 7536, DIN 51554 |

| Sample Volume | 50 grams of oil, 5 grams of distilled water |

| Gas Supply | Oxygen, pressure adjustable to 7 bar ± 0.2 bar |

| Device Capacity | Up to 10,000 test results stored |

| Operating Temperature | 0°C to 50°C |

| Power Supply | 1200W minimum, stable power connection required |

| Dimensions | W: 40cm D: 50cm H: 60cm |

| Weight | 25 kg |

| Display | 7-inch touch screen interface |

| Accessories Included | Sample temperature probe (1 pcs), sample glass container (2 pcs), oxygen hose (6 m), copper coil (5 pcs), etc. |

| Safety Features | Leak test, system check, and gas release functions |