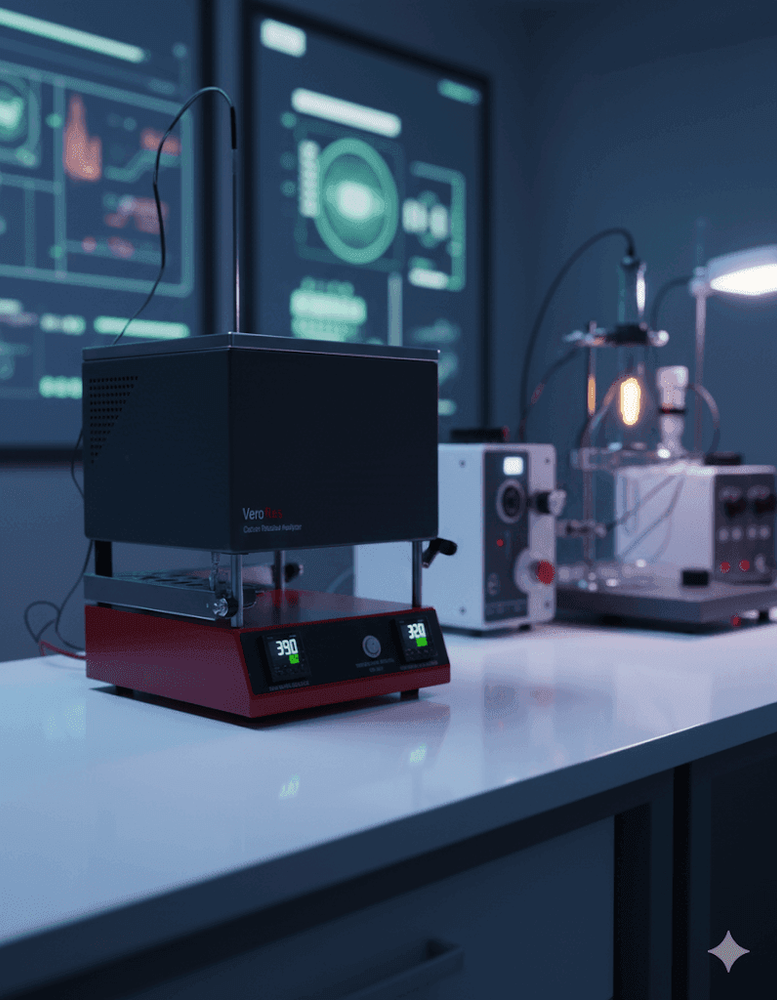

VeroRes Carbon Residue Analyzer ensures accurate and consistent results in full compliance with global testing standards. Designed with a compact dry-bath furnace, it eliminates messy oil baths and the need for external nitrogen. With ±1 °C temperature stability, capacity for five samples, and a rapid 20-minute heat-up to 550 °C, VeroRes delivers reliable, safe, and cost-efficient carbon residue analysis. This makes it an ideal solution for modern laboratories, refineries, and research centers seeking higher throughput and reduced maintenance

CARBON RESIDUE ANALYZER

The VeroRes Analyzer delivers fast, safe, and precise Ramsbottom carbon residue testing. With a compact dry-bath furnace, no nitrogen requirement, and rapid 20-minute heat-up, it ensures accurate results and higher lab efficiency in full compliance with ASTM D524, ISO 4262, and IP 14

Standarts

Correlations

Highlights

The VeroRes Carbon Residue Analyzer is engineered to deliver fast, accurate, and repeatable results, making it an essential tool for evaluating carbon residue in fuels, lubricants, crude fractions, and heavy oils. By precisely heating samples to 550–650 °C under controlled conditions, VeroRes provides reliable insights into deposit formation, fuel quality, and refining process optimization

Equipped with advanced dry-bath furnace technology, the device eliminates messy oil baths and the need for nitrogen, ensuring safe and clean operation. Its compact design supports simultaneous testing of up to five samples while maintaining ±1 °C stability, boosting laboratory productivity by over 40%. Designed for both user-friendliness and durability, VeroRes features rapid 20-minute heat-up cycles, minimal maintenance requirements, and full compliance with ASTM D524, ISO 4262, and IP 14. This establishes VeroRes as a trusted solution for refineries, R&D centers, and industrial laboratories worldwide.

Videos

Comprehensive Overview of the VeroRes – Advanced Carbon Residue Testing for Fuels and Lubricants

- Standard Methodology: Learn how VeroRes follows ASTM D524 and ISO 4262 for accurate determination of Ramsbottom carbon residue.

- Step-by-Step Demonstration: See the entire process, from preparing glass coking bulbs to precise heating in the dry-bath furnace.

- Application Benefits: Understand how VeroRes supports refineries, research centers, and quality control labs with reliable test data.

- Clean & Safe Operation: Discover how the nitrogen-free, oil-free furnace ensures safer, more efficient laboratory work.

Maximizing Laboratory Efficiency with the VeroRes – Faster Heating Cycles, Higher Sample Capacity, and Significant Cost Reductions

- Rapid Heat-Up: VeroRes quickly reaches the standard test temperature of 550 °C in only ~20 minutes, making it nearly three times faster than conventional oil-bath systems. This speed allows laboratories to shorten preparation times and conduct more tests within a single working day.

- Multi-Sample Testing: With the ability to process up to five glass coking bulbs simultaneously, the analyzer significantly increases throughput while ensuring every sample is exposed to the same controlled heating environment for accurate comparisons.

- Precise Control: Its advanced microprocessor ensures ±1 °C temperature stability, guaranteeing consistent and repeatable results even across extended testing schedules. This level of precision is essential for critical applications such as refinery feedstock evaluation and fuel quality monitoring.

- Cost Savings: Thanks to its dry-bath furnace design, VeroRes requires no nitrogen supply and eliminates oil bath maintenance, cutting recurring expenses. The only consumables are inexpensive glass bulbs, making the system both economical and sustainable for long-term use.

Technical Specifications

| Model | VeroRes – Carbon Residue Analyzer |

| Standards Compliance | ASTM D524, ASTM D6074, IP 14, ISO 4262, FTM 791-5002, NF T 60-117 |

| Furnace Type | Cast-iron block, microprocessor-controlled with digital setpoint & display |

| Capacity | 5 coking bulbs (simultaneous testing) |

| Maximum Temperature | 650 °C (standard test temperature 550 °C) |

| Controller Sensitivity | ±1 °C for high stability measurements |

| Heating System | 0–2400 W ceramic band heater, rapid heat-up (~20 minutes to 550 °C) |

| Over-temperature Protection | Automatic cut-off safety circuit |

| Construction | Stainless steel + insulated design to prevent heat transfer to body (keeps outer surfaces safe to touch) |

| Dimensions | Compact footprint, smallest RAMS furnace in its class (exact size optimized for benchtop labs) |

| Sample Range | Residual carbon determination via evaporation & pyrolysis – suitable for petroleum products, lubricants, asphalts, and heavy oils |

| Power Supply | 220 V / 50–60 Hz |

| Maintenance | No oil bath, no nitrogen required; minimal servicing – only consumables are inexpensive glass coking bulbs |