Designed to help industries evaluate foaming tendencies in lubricants, the VeroFoam ensures that oils meet stringent performance standards even under challenging conditions involving turbulence or high-speed systems.

Foaming in lubricants can cause operational issues, including inadequate lubrication, cavitation, overflow, and premature oxidation. The VeroFoam is specifically designed to address these challenges by providing accurate measurements of foaming characteristics, allowing operators to maintain consistent lubrication quality and equipment performance.

Understanding Foaming Tendency

Foaming tendency refers to the ability of a lubricant to generate foam under turbulent conditions or aeration. Excessive foam can cause serious problems, including improper lubrication, increased oxidation, and damage to seals and other components. The VeroFoam measures foam formation and collapse rates to help industries evaluate the stability of lubricating oils. By providing detailed insights, the VeroFoam ensures that oils perform effectively in demanding environments, enhancing the reliability and efficiency of machinery.

Key Features of the VeroFoam

Methodology Compliance (ASTM D892/D6082)

The VeroFoam adheres to established ASTM standards, ensuring consistency and accuracy in evaluating the foaming properties of Newtonian liquids. This compliance makes the analyzer suitable for industries that require rigorous quality control and adherence to standards.

Temperature Range of 5°C to 150°C

The VeroFoam is capable of operating within a wide temperature range, making it versatile for various testing scenarios. The optional chiller allows for lower temperature testing, further expanding its application range. The temperature resolution is set at 0.1°C, which allows for precise control throughout the testing process, ensuring reliable and repeatable results(Verosci_UM8_FA200_compr…).

Dual Oil Bath System

The VeroFoam features two separate oil baths, each with a volume of 6-8 liters, which enables simultaneous testing of multiple samples. This dual-bath configuration helps maximize throughput, enhancing efficiency in laboratories and industrial settings. Each bath can be independently controlled to ensure accurate testing conditions(Verosci_UM8_FA200_compr…).

Automated Sample Capacity

The device can handle up to four samples simultaneously, making it ideal for labs with high testing volumes. Automation reduces the need for manual intervention, which minimizes the risk of human error and increases the efficiency of the testing process.

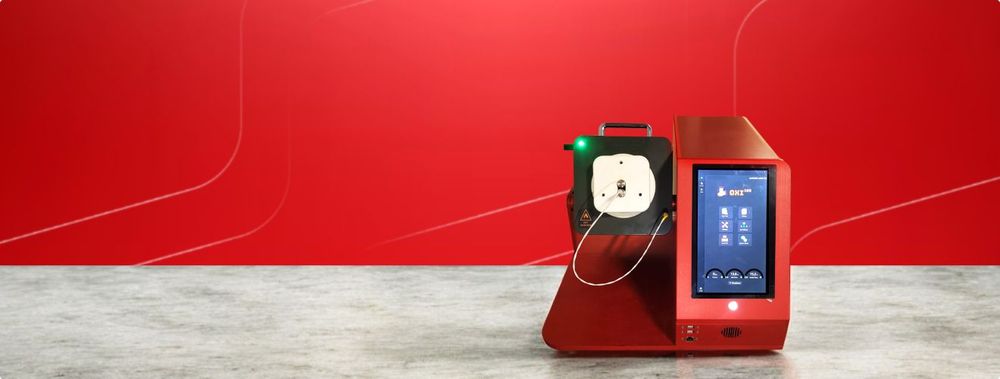

Advanced User Interface

The VeroFoam comes with a 10.1-inch capacitive touchscreen that is powered by a Windows 10 operating system. This intuitive interface allows users to easily input testing parameters, monitor test progress, and view results in real-time. The device also offers USB ports and an Ethernet connection, ensuring seamless data transfer and connectivity.

Air Flow Control

The VeroFoam includes a dry air inlet that supplies air to the device at a pressure range of 2-3 bar. The airflow is precisely controlled, which is crucial for consistent and accurate foaming tendency testing. The air inlet ensures that air is introduced into the lubricant sample uniformly, thereby replicating real-world conditions during testing.

Result Storage and Reporting

The VeroFoam can store up to 10,000 test results, allowing for easy data retrieval and historical trend analysis. The test results can be saved in PDF format, making it simple to generate reports for quality assurance and compliance purposes. This large storage capacity is particularly useful for organizations that need to maintain long-term records for quality control.

Rapid Cooling System

The VeroFoam includes coolant inlets and outlets that allow for rapid cooling of the bath oil, reducing the waiting time between tests and increasing throughput. This capability is essential for labs that require quick turnaround times on testing results.

Benefits of Using the VeroFoam

The VeroFoam, Foaming Tendency Analyzer, provides a host of benefits for industries that rely on high-quality lubricants:

Enhanced Lubricant Performance

The VeroFoam helps identify lubricants that are prone to foaming, ensuring that only high-quality products are used in machinery. This assessment helps optimize lubricant performance, ensuring consistent and reliable lubrication under real-world conditions.

Operational Efficiency

With its dual oil bath system and automated sample handling, the VeroFoam allows multiple tests to be conducted simultaneously, maximizing operational efficiency. The rapid cooling system further enhances throughput by reducing downtime between tests.

Automated, Accurate Testing

The VeroFoam's fully automated operation minimizes the risk of human error and ensures consistent test results. Accurate temperature and air flow control make it possible to achieve highly reliable data, which is essential for quality control.

Compliance with Industry Standards

By adhering to ASTM D892 and D6082 standards, the VeroFoam ensures that test results are consistent with industry requirements. This compliance is crucial for lubricant manufacturers and users who need to maintain product quality and meet regulatory standards.

User-Friendly Design

Applications of the VeroFoam

The VeroFoam Foaming Tendency Analyzer is suitable for a variety of industries and applications:

- Automotive and Aerospace Industries

Evaluating the foaming characteristics of engine oils, transmission fluids, and hydraulic fluids used in high-speed, high-stress environments.

- Industrial Machinery

Ensuring that lubricants used in machinery maintain stability under turbulent conditions to prevent wear and damage.

- Oil Refineries and Lubricant Manufacturers

Quality control testing for lubricating oils to ensure they meet required specifications and perform effectively in real-world conditions.

- Power Generation

Monitoring lubricants used in turbines and other rotating equipment to ensure reliable operation and minimize foam-related issues.

VeroFoam: A Benchmark for Lubricant Stability Testing

The VeroFoam, Foaming Tendency Analyzer, from Vero Scientific sets a new standard for lubricant testing by combining precision, automation, and compliance with industry standards. Its advanced features make it an essential tool for industries that rely on high-quality lubricants to maintain equipment reliability and performance.

By accurately evaluating the foaming properties of lubricants, the VeroFoam helps industries prevent equipment failures, minimize operational risks, and maintain high-quality standards. Vero Scientific is committed to providing advanced solutions that empower industries to achieve greater efficiency and reliability. For more information on the VeroFoam and how it can benefit your business, contact Vero Scientific today.