The EVA101 Closed-Loop Evaporator is designed for accurate moisture analysis in oils, lubricants, and other viscous liquids. It complies with key standards like ASTM D6304, IP 398, and DIN EN ISO 12937, all of which use the coulometric Karl Fischer method for water determination. These standards ensure reliable and repeatable results, making the EVA101 ideal for moisture testing in the petroleum and lubricant industries.

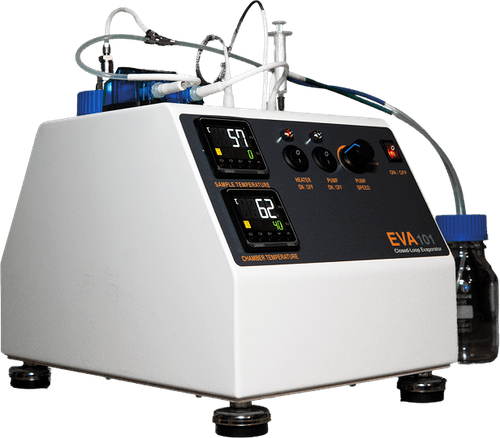

EVA 101 - CLOSED LOOP EVAPORATOR

The EVA101 Closed-Loop Evaporator is a state-of-the-art device designed for precise moisture analysis in lubricants, grease, and other viscous liquids. It complies with ASTM D6304 standards, ensuring solvent-free, efficient, and repeatable results in laboratory environments.

Standarts

Correlations

Highlights

The EVA101 Closed-Loop Evaporator is a cutting-edge device designed to provide precise and efficient moisture analysis for a wide range of viscous liquids, including lubricants, grease, tar products, and paint. By utilizing a solvent-free indirect titration method, the device eliminates the need for frequent waste disposal, enabling up to 30 consecutive tests without interruptions.

This advanced device is equipped with transparent chambers for real-time monitoring and PID temperature control for precise heating up to 200°C. Its robust construction using high-quality materials ensures long-lasting performance in demanding laboratory environments.

With its compact design, intuitive controls, and compatibility with Karl Fischer titrators, the EVA101 simplifies complex moisture analysis, delivering reliable results while prioritizing user safety and environmental sustainability.

Videos

EVA101: The Ultimate Solution for Solvent-Free Moisture Analysis in Viscous Liquids

- Solvent-Free Testing with Up to 30 Consecutive Runs: The EVA101 allows for up to 30 tests without the need for waste disposal between runs, ensuring high efficiency and minimal environmental impact.

- Precise Temperature Control with PID Technology: Equipped with advanced PID temperature control, the EVA101 delivers highly accurate and stable heating, with the ability to reach temperatures of up to 200°C in just two minutes.

- Transparent Evaporation Chamber for Easy Monitoring: The transparent chamber provides full visibility of the sample, allowing users to track the evaporation process and monitor progress without opening the device.

- Compliance with ASTM D6304 Standards: The EVA101 meets the rigorous requirements of ASTM D6304, ensuring reliable and industry-standard results for moisture testing in petroleum-based products and other viscous liquids.

A Comprehensive Guide to Using the EVA101 for Accurate and Efficient Moisture Testing

- Simple and Intuitive Setup Process: This video guides users through the easy-to-follow setup process, ensuring the EVA101 is ready for use in just a few steps, providing quick and accurate results.

- Adjustable Pump Speed and Temperature Controls: With fully adjustable settings for pump speed and temperature, users can optimize the EVA101's performance for a wide range of sample types, improving the efficiency and accuracy of moisture testing.

- Compact and Durable Design: The EVA101's compact, lightweight structure makes it easy to integrate into any laboratory setting while maintaining a robust build for long-term use and consistent results.

- Full Compatibility with Karl Fischer Titrators: The EVA101 is compatible with most leading coulometric and volumetric Karl Fischer titrators, offering versatile options for moisture testing across various applications.

Technical Specifications

| Model | EVA 101 Closed-Loop Evaporator |

| Methodology | ASTM D6304 |

| Monitoring | Chamber and sample temperature |

| Heating Capacity | From Ambient to 200°C (with the ability to reach 150°C in 2 minutes) |

| Evaporator Chamber | Pyrex glass – Teflon with maximum capacity of 50 mL |

| Peristaltic Pump Capacity | 50 mL/min to 500 mL/min |

| Test Chamber | Stainless steel, teflon, glass material |

| Device Operating Enviroment | Max. 10°C to 50°C |

| Power Output | 200 W |

| Power Requirement | 220 VAC – 50 Hz |

| Dimensions | W: 23cm x D: 32 cm x H: 31 cm |

| Net Weight | 8 kg |